Mounting a DRO on the Sheldon lathe at work

May, 2016

You can get by no problem with dial indicators and the built in X axis screw dial on a manual but if you run one for anything except hobby fun you really need a DRO. A simple DRO doesn't let you do anything that you can't do the old fashion way but it is much quicker and easier, well worth the cost even if it is as expensive the machine itself. Anyway, when I came to the company they had a lathe but no milling machine so I soon purchased a knee mill that had a damaged Mitutoyo DRO and scales. As part of my commisioning of the mill I bought a new counter to go with the existing scales and also purchased scales and a 2nd counter to go on the lathe. I was too busy to mount the DRO on the lathe myself for awhile and the installation was a little more complicated than just bolting it on so it sat for awhile. I finally got some time to mount it though.

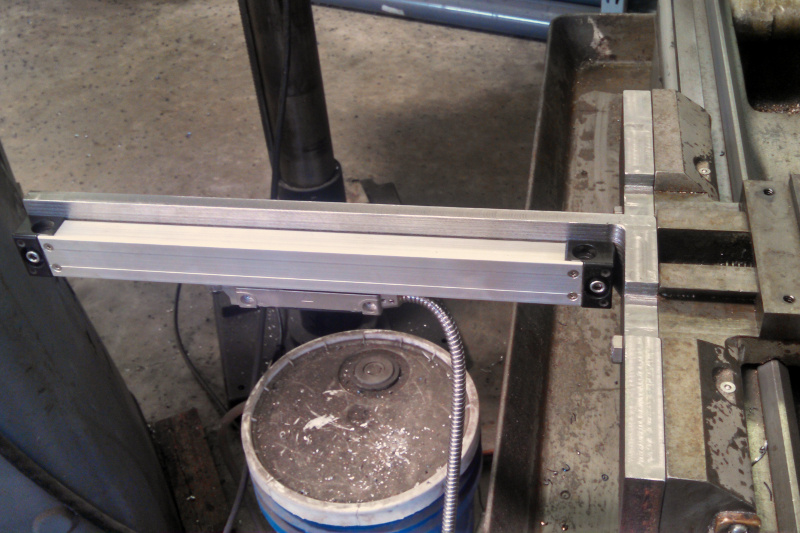

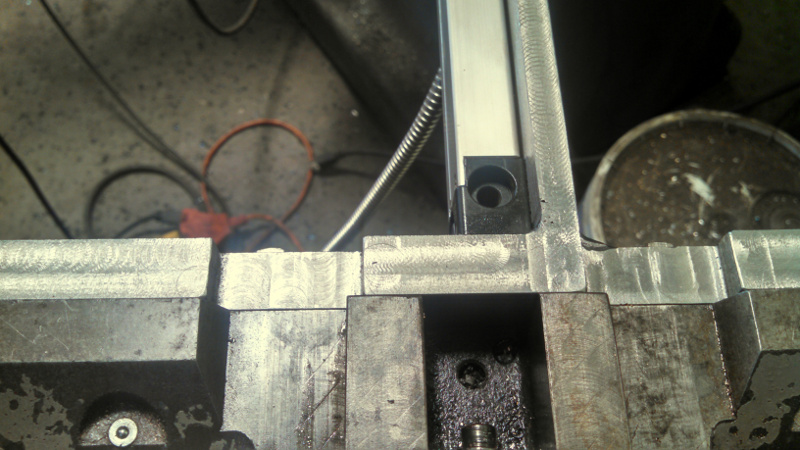

The fundamental problem is that unlike most larger lathes there isn't room for the crossslide scale anywhere. I had to hang it off the back of the carriage. I welded up a T out of mild steel that could bolt onto the carraige with some existing screw holes (I don't like to drill holes in a machine unless I absolutely have to).

I rough milled everything square then came back to touch up all the important dimensions with a finishing pass to make sure it wouldn't moe on me anymore after welding. I didn't spend any extra time on a nice surface finish, just get the critical dimensions right and make sure everything else clears.

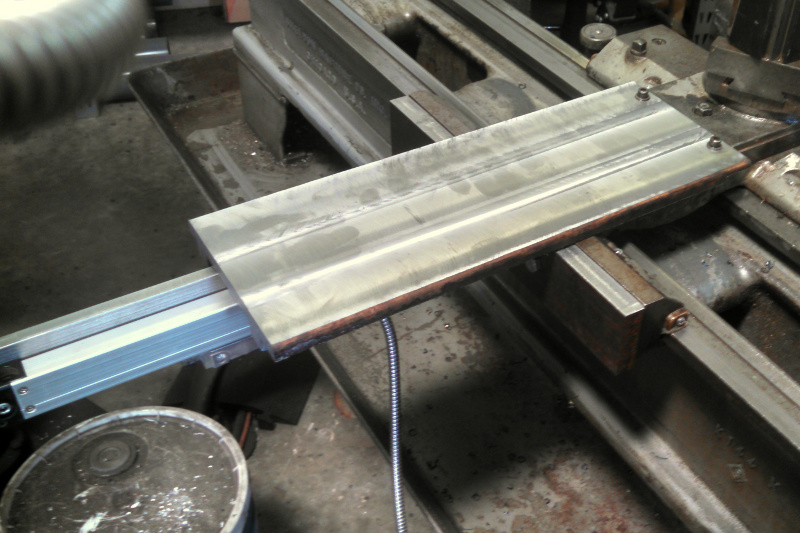

Then I milled a new cross slide cover out of some 1" thick mild steel flat bar.

Before I could finish the cover I had to temporarily install it to mark where the mounting holes for the read head needed to be

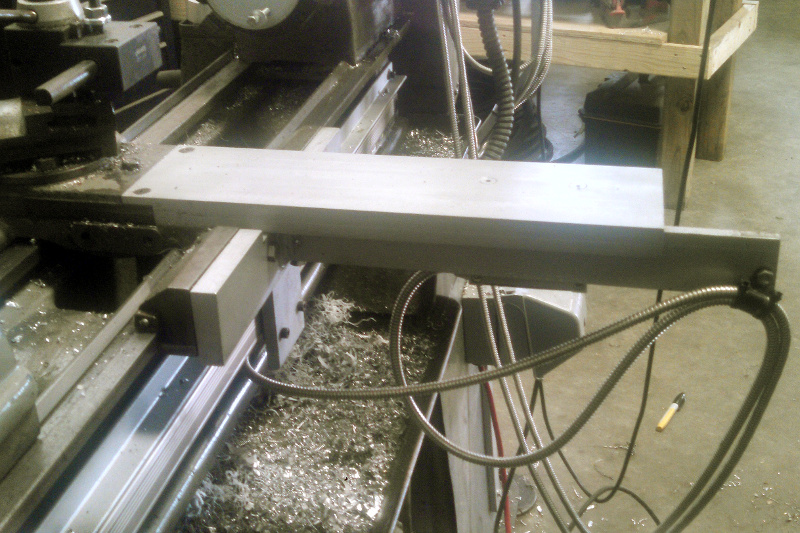

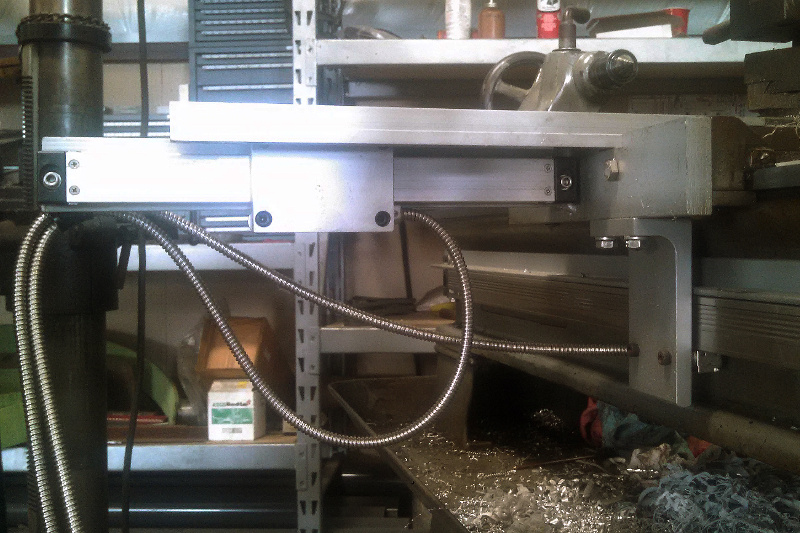

Next the Z axis goes on. I did have to drill a couple of holes to mount the scale but the reader head attaches to the T bracket I already made.

Here it is from the other side, all painted and prettied up. The cables are certainly a little goofy and look bad but they don't get caught on anything and I don't foresee any problems. They hang well out of the way and don't get caught up in stringy chips.

And last mount the counter unit. Again, no additional holes in the lathe, I made my mounting bar pick up some existing holes on a back cover. While I was at it I also added a weatherproof outlet that the DRO, lathe and coolant pump plug into. That really cleaned up the wiring back there.