Don't buy taps at the hardware or autoparts store!

Title pretty much says it all. Don't buy taps at Lowes, Homedepot, Ace, Truevalue, Autozone, Oreilly, Advanced, NAPA, Harbor Freight or anywhere that primarily sells things to consumers. They only have overpriced crap with lousy materials and horrible cutting geometry. They might work for cleaning gunk out of an existing hole but that is it.

Now I have known this for a long time but when I was a little younger and more optimistic I made a couple of mistakes in spite of that knowledge. One time I had a paying part for someone that required taping an aluminum 6061-t6 hole with an oddball metric thread. I really wanted to get the part finished quickly without waiting around for the tap I needed to come in so I looked in town and managed to find one at an autoparts store. I thought, hey it is only aluminum right? Surely even a bad tap can manage to thread on hole. Nope, the grind was way off and it didn't cut at all. After 20 minutes carefully touching it up with the bench grinder and hand stones I corrected the geometry and made it cut but it wasn't worth the slightly lower cost and convenience.

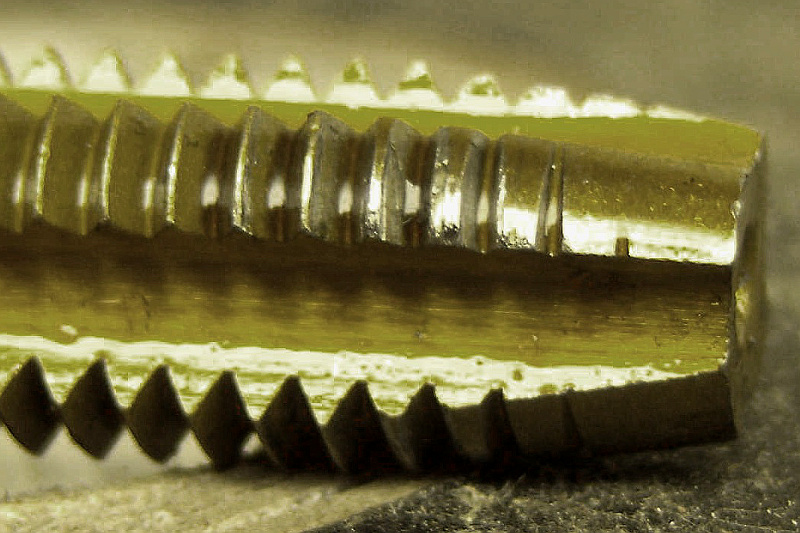

Another good example was working on that little ENCO lathe I briefly had in California. One of the holes on the 4 way toolpost was a little off size or buggered up so I needed to re-tap it. At that time my tap collection wasn't very complete yet so I didn't have a good one and that thread was one of the few things I had left so I really wanted to finish it that weekend. That lead me to buy a hardware tap and here is what the hole did to it:

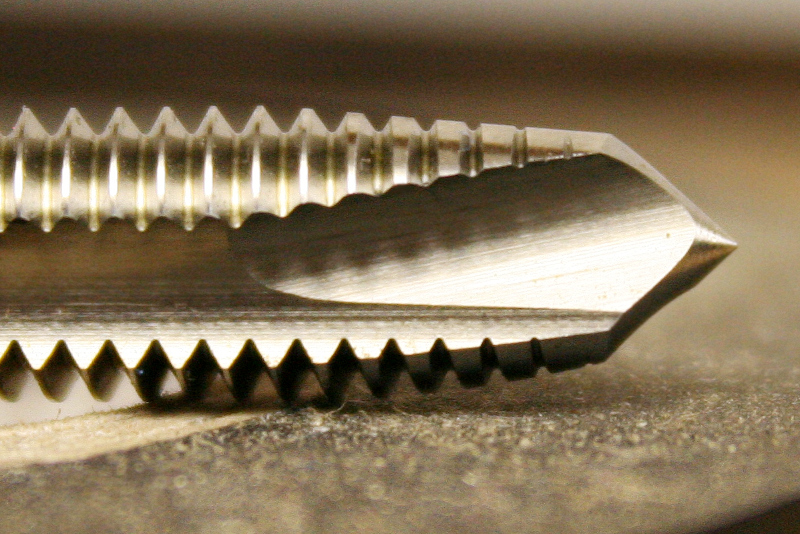

Just cutting one hole totally buggered up the cutting edges on that thing. So much for the fancy titanium nitride coating! I didn't even get it all the way through the hole, it go too hard to turn and I was scared I would snap it off so I decided to do what I should have done in the first place, hold off and wait for a good tap to come in that mail. So next weekend I took my brand new uncoated, high speed steel OSG tap and cleaned up that hole no problem at all. For comparison here is what it looked like after cleaning up the hole, no change at all:

So don't buy crappy hardware or autoparts store taps. Stock up beforehand on individual taps from reputable makers on ebay to build your collection so you have everything covered. If you don't have what you need and have to get something quick just pony up and pay whatever it costs to get the quality tap at the shipping speed you are willing to pay for. It is worth it.

Tap types

So what is a good tap? Well some brands that I like are OSG, Widia/Greenfield ,Guhring, Morse, Dormer / Union Butterfield. Vermont also has some good ones but in general watch out for those unless they are old, they make some hardware store grade crap.

So those are a few brands that might be worth keeping an eye out for but what about all the different geometries and coatings? The answer is simple on the coatings, unless I am planning a project with stainless or high nickel materials I almost always go uncoated or at least don't pay extra for one. Most small/home shop usage is for onsie-twosie usage in varying materials and often done by hand. Coatings really need to be matched to the material and really only come into play most of the time when conditions are more like a production environment with 100's of holes as fast as possible.

I am a little more all over the place with tap geometries than coatings though. There is a place for thread forming taps, combined drill-taps, tapered hand taps, bottoming taps, spiral flute taps etc.. and I have a few of each of those types but the preferred standard that I stock in all sizes is a spiral point (gun type) plug-chamfer tap. They can be a little harder to start in a hole than a tapered hand tap sometimes but since they push the chips ahead into the hole you can power tap in one shot or never back off when tapping by hand. They also thread close enough to the bottom of a blind hole to give enough thread depth in almost all applications.

If you don't know what the spiral point plug-chamfer tap is then just look back at that picture of the OSG tap, it is exactly that

Tap clearance

One more thing about taps before I forget. They don't all cut the same size hole even if they are the same size. The thread size (IE 1/4-20UNC) tells you what the nominal dimensions for the tapped hole are but there is always some clearance so that screws fit into tapped holes. Anyway, I could get diverted on that topic for quite awhile, what is important to know is that both metric and sae taps have a number that tells you what the clearance with respect to the nominal dimension is. For SAE (inch) taps this is represented by the pitch diameter allowance H3, H11 etc... multiply that pitch diameter limit number by .0005" and you get the nominal clearance over the basic pitch diameter. IE, a standard 1/4-20UNC tap will generally be a H3 which is .0015" over the basic pitch diameter. That puts it perfectly in the class 3B tolerance range and gives a nice tight feeling hole. For a sloppier feel like a galvanized hardware store bolt and nut you would go with a H4 or H5 tap.

Basically for general usage the right tap is likely: H1 for holes smaller than 4-48, H2 for holes up to about 10-32, H3 up to about 3/4-10 and H4 up to 1-1/2 - 6.

Obviously if you have a critical application you should know what is required and look it up yourself but those numbers are close enough for general usage most of the time.

In addition to the standard clearance taps I also have a fair number of .005" (H11) oversize ones on hand in the 3/8" to 1" range. They are useful for parts that I will hot dip galvanize. I tap oversize, galvanize and then re-tap with a standard size tap leaving a few thousandths of zinc plating to protect the threads.