Assorted items I've machined

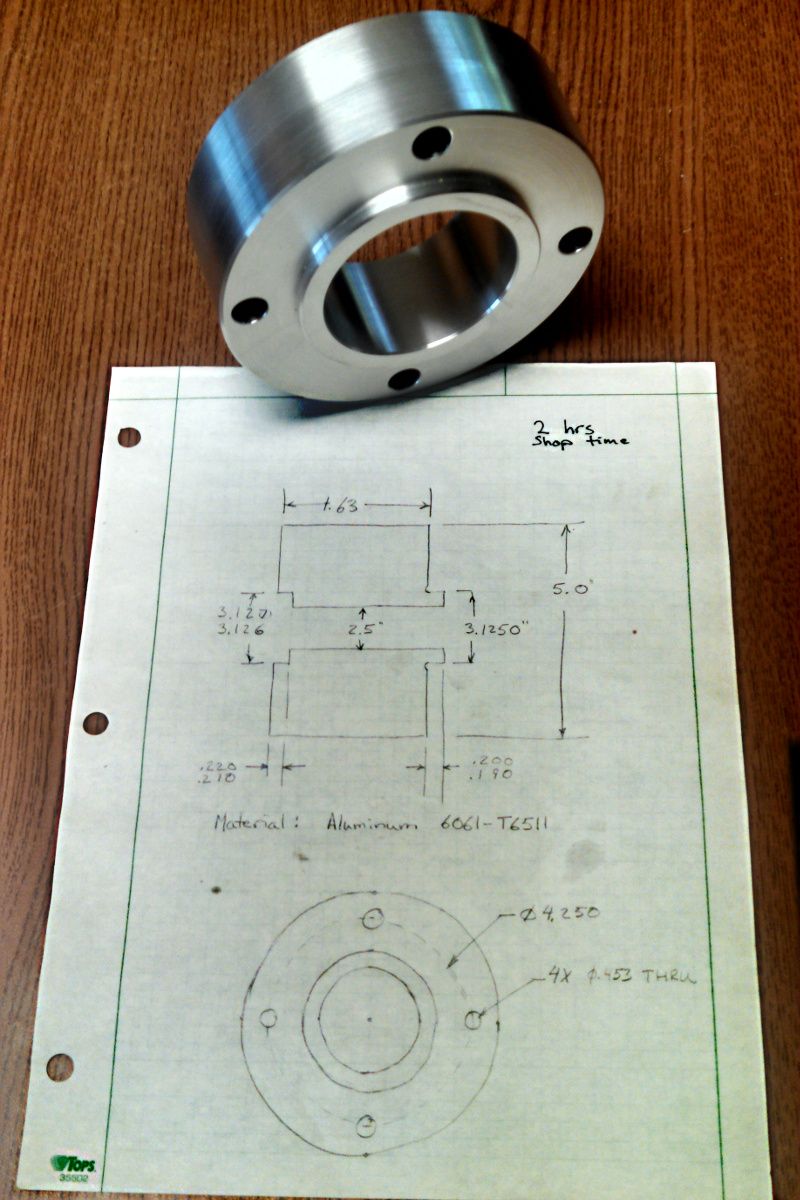

Differential Spacer

2016

Someone needed a custom spacer to move the u-joint on the drive shaft going to their differential out just a little bit. Not a big project but one that made me wish I had my larger lathe set up and running so I could actually take a decent cut.

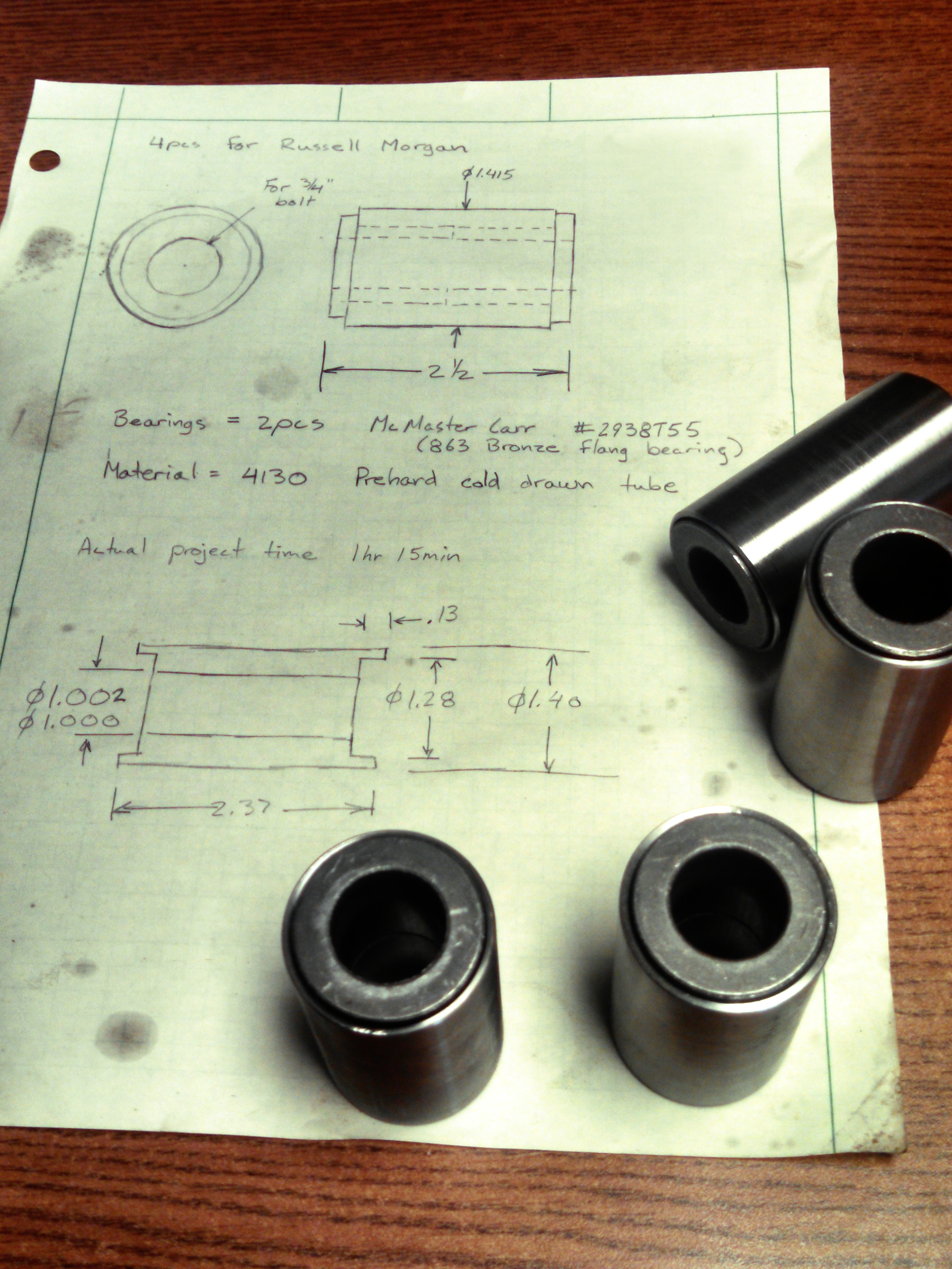

4140 Prehard Rollers

2016

A previous co-worker needed some rollers to help guide a bin on a dump truck or something. I made them out of pre-hard 4140 DOM (drawn over mandrel) tube and commonly available 863 bronze (high load oil impregnated with iron) bushings.

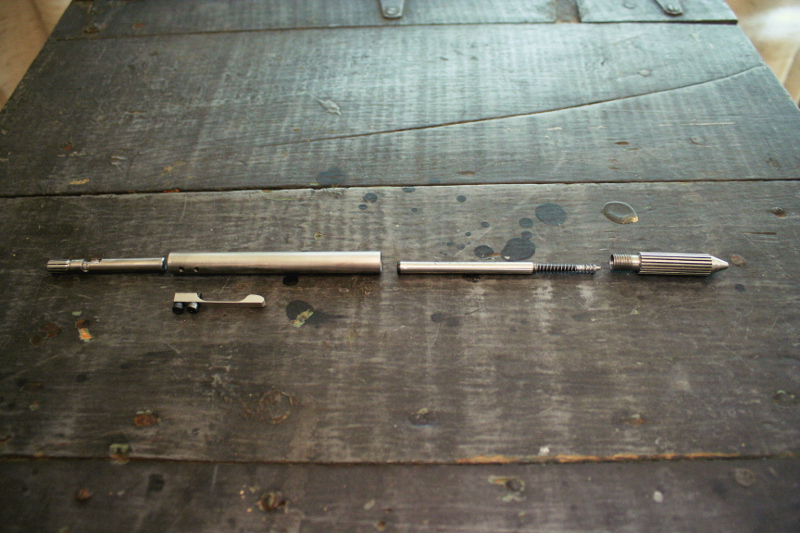

Stainless Pens

2011

One of my earlier just for fun machining projects were some pens made on my first lathe, the Logan and my first milling machine, the Industro-Lite.

There are some cool parts about these pens. First of all the one with the "knurling" in the grip area had that put on by using the lathe a a kind of shaper. Lock the spindle in position then run the carriage back and forth by hand a few times to cut a groove. Rotate the spindle and do it again for the next groove.

Second, the mechanism is a little different than any you have seen before. To extend the tip you push the end knob down and twist at the same time then to retract you just twist the knob the other direction and the spring pushes it back up. This is accomplished by a t-shaped groove in the knob which matches a longer screw used to hold the clip on. Simple and easy to make but effective.

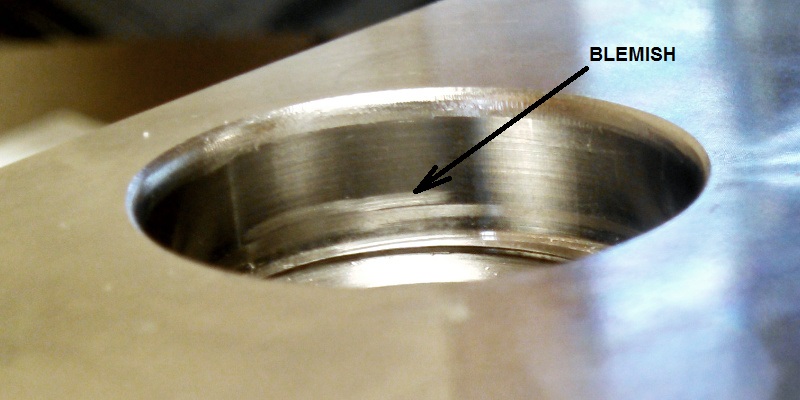

Handwork

2014

Machinists generally dislike handwork on their parts. A slip by unskilled or tired hands can ruin things in a hurry. A machine shop messed up a very expensive part I ordered for my day job by tagging a super tight tolerance feature with the tool they were using to hand debur some threads with.

Fortunately the nature of the sealing surface allowed the part to be saved by boring it oversize, coating it in electroless nickel then re-grinding it to final size.

Accelerometer Housing

2015

I frequently machine one off parts and prototypes for my day job. Here is one fun part I can show. It is a housing made out of 17-4PH HH1150 (really strong and dimensionally stable stainless steel) for a tiny accelerometer data logger that lets me attach it inline with a set of rods that move.

Unfortunately since I was in a rush on this part I didn't have time to get a thin layer of copper plate applied. Since the high pressures it operates at require very tight tolerances and 17-4 likes to gall it is often wise to plate it with something else. Anyway, at some point it got dinged or scratched which caused it to gall up upon assembly. On version 2 I had time to copper plat the important parts. Pretty!